The company, Micro Power, was founded in the year 1989. From the beginning of the company existence until now, Micro Power has been involved in Load Monitoring applications, primarily in the area of Tool Monitoring but also for monitoring Pumps, Cranes, Conveyors, Fans etc. Any machine that includes a Motor (AC, DC or Variable Frequency Inverter driven) can very often benefit from Load Monitoring based on a fast and accurate Power-Measurement. The purpose of the Load Monitoring is not to protect the motor, but to protect the machine from damage. Recently we have successfully been monitoring high speed spindles (60.000 rpm) with our 3 phase, shunt based, Load Monitor.

In the beginning of the year 1990, Micro Power did develop the first digital Tool Monitors, based on Load Monitoring of the cutting spindle, for the German company ARTIS, which today is owned by MARPOSS. In the recent like 20 years Micro Power has been developing and delivering Tool Monitoring Products mostly for the North American Market.

From year 1990 until year 2000 Micro Power did develop the UniPower® family of Load Controllers together with another Danish Company. Even the name UniPower® originated from Micro Power. Micro Power did all the digital part of the development and the other company basically did the analog design, manufacturing and sales. The UniPower® Load Monitors were always based on the use of a Current Transformer for current measurement and the units were not completely digital.

Micro Power ApS is the designer of the Techna-Check® family of Tool Monitoring products. The design and maintainance of the Techna-Check® family has now ended. Micro Power ApS does still own most of the Techna-Check® hardware and software.

Today Micro Power develops Load Controllers and Power Monitors that uses Current Transformers, Hall Sensors or Shunt Resistors for the current measurement. The new power measurement family, to be released from Micro Power, are true digital and they are much more precise than anything Micro Power has been developing together with other companies in the past.

The most accurate transducer made for Tool Monitoring by Micro Power uses 18-bit Analog to Digital Fully Differential Conversion and a sampling rate of 160 kHz (3 currents and 3 voltages are sampled at that rate). This unit is a 3-phase shunt based current measurement unit and considered to be the most accurate power transducer available for Tool Monitoring today. The sampling rate is high enough to guaranty a very accurate measurement when used with Variable Frequency Inverters including High Speed Spindles. This technology is soon going to be available for Load Monitoring applications.

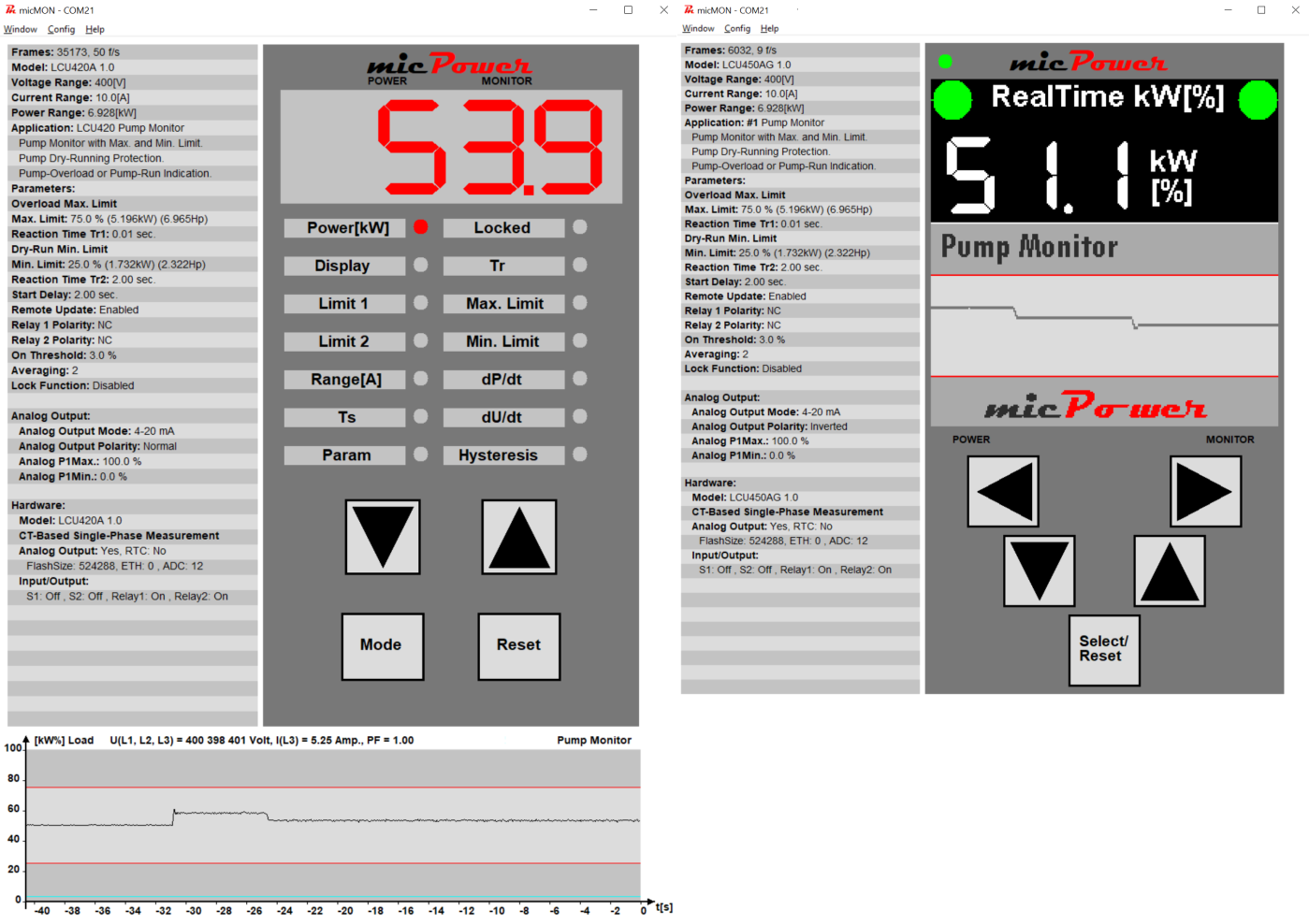

Soon a new family micPower® of Load Controllers & Power Monitors will be released by Micro Power. They are all able to measure power both before and after a Variable Frequency Inverter. They are more precise than anything Micro Power has been working on before with other companies. The prices will be very interesting compared to competitors. A remote control that is powered from the Load Monitor will be available for many of the units.

Both single-phase (for symmetric loads) and 3-phase (for both symmetric and asymmetric loads) units are to be released. The 3-phase, shunt based, Power Monitor will bring ultra-high precision to the Load Control market. The measurement accuracy will be better than 1% and it will be priced lower than many commercially available single-phase Load Monitors. In our lab we use a 0.05% Power Source for test and calibration of our units. The use of shunt resistors for the current measurement is a guaranty for a linear frequency response, when used with Variable Frequency Inverters. The shunt unit may very well be used as a calibration tool by many of our Power Measurement competitors.

The true digital concept makes it possible for the units to also calculate and display RMS current, RMS voltage and Power Factor. Many more power related variables could be calculated on demand. Even a FFT (Fast Fourier Transformation) of current and voltage signals and the display of harmonic frequencies would be possible.

Back in time Micro Power did implement a few custom specific Load Monitor versions. Micro Power made a proprietary Pump Monitor unit for US based Company Ansimag (Sundyne Inc.) to monitor magnetic sealed pumps from dry-running. Micro Power did delevop a special Variable Speed Pump Monitor for the Danish company Svanehøj Pumpefabrik. A special shock load Monitor was developed for the Danish Company Simatek A/S. A custom specific Power Measurement Device was developed for the Swedish company ALSTOM. In the future Micro Power is well prepared to create specific solutions for other customers.

Stay tuned, much more to come.........

NEWS!!! micMON Windows Application for Remote Control, Visualization and Application Interfacing.